We all are habitual of saying that there is a lot of humidity in the air, a lot of moisture, or no moisture. But how do we measure this term called moisture? We simply say that there is a lot of moisture in the atmosphere, or in the games like cricket, we hear the commentators saying that the pitch has much moisture, so what exactly is moisture, and how do we measure this? This article will explain the moisture analyzer and some of its important aspects.

|

| Quick Guide to Moisture Analyzers |

So, Let's know more about Moisture Analyzer.

What is Moisture Analyzer?

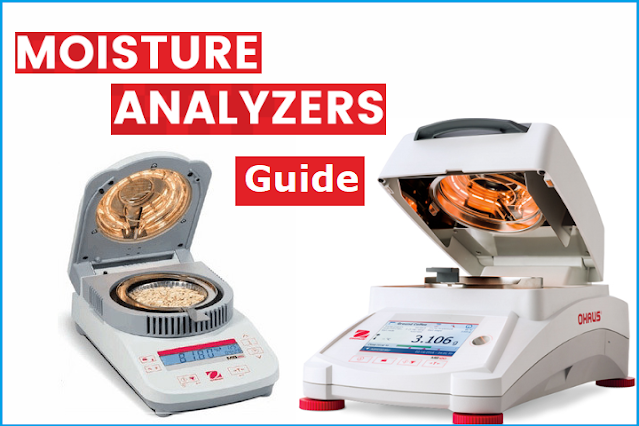

Moisture analyzers, which are also referred to as "moisture balances," are instruments that measure the amount of moisture present in different types of samples, such as solids, liquids, and gases.

Controlling the amount of trace moisture in solids is necessary for manufacturing polymers, medicines, and products that undergo heat treatment. For measuring gases or liquids, the measurement of dry air, the processing of hydrocarbons, pure semiconductor gases, pure bulk gases, dielectric gases like those found in transformers and power plants, and the transportation of natural gas via pipeline.

Automated moisture analyzers have been developed to respond to the slow pace of traditional and manual laboratory procedures for measuring moisture content. These automated moisture analyzers can cut the amount of time necessary for a test from hours to just a few minutes.

Future of Moisture Analyzers Growth

Different types of businesses and organizations make use of moisture analyzers for a wide variety of applications. In the food sector, they can be used to regulate the amount of moisture present. Food that has an excessive amount of moisture runs the risk of becoming stale or encouraging the growth of bacteria.

Additionally, many food items are sold by their weight; hence, it is essential to ensure that customers are not overpaying for water weight. This is because water weight contributes to the overall weight of the food item. On the other hand, if there is not enough moisture in the food, it will have a lower calorie count and will be dry. The moisture level in food significantly impacts its texture, flavor, and look on the shelf, in addition to many other characteristics.

Moisture analyzers are also commonly employed in quality control laboratories and other types of research facilities. The amount of water present in crude oil, fuel, sewage sludge, and a wide variety of other chemicals, solids, and liquids can be determined through the use of moisture analysis, which is utilized in many different fields.

Most moisture analyzers are equipped with a computer interface that can assist in observing and analyzing how the drying process affects the sample. They can keep the tests in their memory, enabling them to repeat frequently used test settings without having to set them up repeatedly, which helps reduce time spent waiting.

How does the Moisture analyzer work?

The moisture analyzer first weighs a sample, then dries it up with heat, and again weighs it once it has cooled down. This is the basic principle of working a moisture analyzer. A common technique for determining the amount of moisture present is referred to as loss on drying (LOD). After being weighed, heated, and dried, the sample is weighed once more to produce more accurate results. When the weight after drying is deducted from the weight before, the difference represents the amount of moisture that evaporated during the drying process.

Various types of moisture analyzers generate heat in a few distinct ways. Some make use of a single halogen bulb rated at 400 watts, which can heat the sample in selected increments of 1 degree Celsius. Because of their speed, efficiency, and responsiveness, halogen moisture analyzer are ideal for moisture analysis, a process in which there is no single setting that heats all samples evenly. While some samples can be dried using constant heating, others must be heated in specific increments to avoid being damaged.

Starting the moisture analyzer, selecting or setting the test settings, placing a sample in a tared dish or sample pan, and then closing the lid to begin the drying process are the basic steps involved in the procedure. The analysis is carried out even as the material is being dried.

It finishes either when the test is finished or after a certain amount of time that the user specifies. In order to conduct in-depth analyses and observations, the data are frequently transferred to computers or saved on flash drives. The reports comply with both ISO and GLP standards.

Calibration of Moisture Analyzer

It is of the utmost importance that you calibrate your moisture analyzer regularly since if the variances are too much, the moisture content could be incorrect, or the samples could be damaged. When certain samples burn, they have the potential to cause problems in the laboratory as well as harm to the moisture analyzer.

It is important to ensure that you have read the information manual of the equipment correctly to know the heating and drying settings and the substances you should not put in your PMB. Always be aware of your materials, as some temperatures or drying methods can cause the materials to burn, create smoke or even explode.

Basic steps to follow while calibrating your moisture analyzer

- Make sure the moisture analyzer has been on for about an hour, and if you use it, let it cool down for three hours.

- Put a pan of samples in the PMB.

- Place the temperature probe on the sample pan. This will be used to keep track of the temperature.

- Put the door back on.

- Go to the menu and choose "calibration."

- Choose CAL TEMP, which stands for Temperature Calibration.

- Hit the [Setup/Enter] button. The display will walk you through the steps necessary to calibrate the heating chamber's temperature.

- When the analyzer chamber is closed, 00:00 will show on the screen, and the timer will start. The timer will count up to 20:00 to allow room time to reach a steady temperature (room temperature). During this time, keep an eye on how hot or cold the chamber is. Every minute, the beeper will go off to let you know that the calibration is still going on.

- Take note of how hot or cold it is inside the chamber. Press [Setup/Enter] when the temperature has been stable for a while to enter the lower temperature. Enter the temperature inside the chamber using the number method.

- To keep going with the test, press [Setup/Enter]. The heaters will turn on, and the test chamber will start warming. As before, the timer will show how much time has passed. The temperature in the chamber will be around 150 Degrees Celcius. The buzzer will go off after 20 minutes.

- To enter the second temperature value shown, press [Setup/Enter]. Like before, type in the second value and press [Setup/Enter] to confirm and save it. The PMB will now go back to its regular weight.

So, this is all about the moisture analyzer and why it is so essential in specific industries. Considering that such moisture analyzers are in huge demand from various industrial segments. The market for moisture analyzers is proliferating and will soon be one of the significant revenue-generating segments in the global market.